When you think of stainless steel, you might picture kitchen cookware or building rebar. Yet have you ever considered that the scalpel in a surgeon’s hand, the orthopedic plates implanted in a patient’s bones, and even the tiny stents that save countless lives all originate from this seemingly ordinary metal? Medical-grade stainless steel is modern medicine’s invisible hero—it must withstand the body’s hostile environment while delivering antimicrobial action, high strength, and biocompatibility. Today, we unveil its technological secrets.

1. Surgical Instruments & Orthopedic Implants: “Hardcore” Requirements

1.1 Surgical Blades: Sharpness Meets Sterility

A surgical blade’s alloy must combine three critical properties:

- High strength to hold a razor edge

- Corrosion resistance against bodily fluids

- Sterilizability in autoclaves at high temperature and pressure

Ordinary 304 stainless steel, though inexpensive, can suffer pitting or intergranular corrosion when repeatedly exposed to blood, tissue fluids, and sterilization cycles—releasing metal ions that may trigger inflammation. Therefore, 316L stainless (with 2–3% molybdenum) is the standard choice in surgical instruments:

- Alloy upgrade: The added Mo greatly improves chloride-resistance, preventing rust in saline environments.

- Surface finish: Electropolishing yields a mirror-smooth surface, reducing bacterial adhesion and eliminating microcracks, which lowers infection risk.

- Ultra-clean purity: Non-metallic inclusions are held to Grade 1 (a far stricter standard than industrial steel), ensuring uniformity and long-term stability.

1.2 Orthopedic Implants: Metals That “Live” with Bone

Bone plates, screws, and other implants must perform flawlessly for decades inside the body. Key demands include:

- Mechanical compatibility: Traditional stainless (elastic modulus ≈200 GPa) is much stiffer than bone (≈20 GPa), risking stress-shielding and bone loss. High-nitrogen, nickel-free stainless steels (per GB 4234.9-2023) add 0.25–0.50% nitrogen to double strength while reducing nickel (hence allergy risk).

- Corrosion resistance: Implants endure constant exposure to body fluids, verified by copper-copper sulfate intergranular corrosion tests to ensure welds and cold-worked sections won’t crack.

- Biocompatibility: Strict limits on chromium and nickel ion release prevent tissue necrosis or systemic toxicity.

2. 316L’s “Superpowers”: How It Stays Clean & Strong

2.1 Corrosion Shield: Molybdenum’s Role

Molybdenum in 316L forms a dense MoO₃ film on the surface, blocking chloride ions (e.g., NaCl in blood) and preventing pitting. In simulated body fluids, 316L’s corrosion rate is just 1/10 that of 304.

2.2 Antimicrobial Action: Dual-Strategy

- Electropolishing removes microscopic crevices, leaving few niches for bacteria.

- Silver-ion coatings on high-end instruments harness silver’s broad-spectrum biocidal power, further cutting infection rates.

- Low-surface-energy treatments render the steel hydrophobic, inhibiting biofilm formation.

2.3 Cold-Work Strengthening: The Blade’s Edge

In solution-annealed 316L, tensile strength is ~500 MPa. But 20–30% cold rolling can boost that to ~1000 MPa while retaining good toughness—ensuring blades stay sharp under extreme cutting demands.

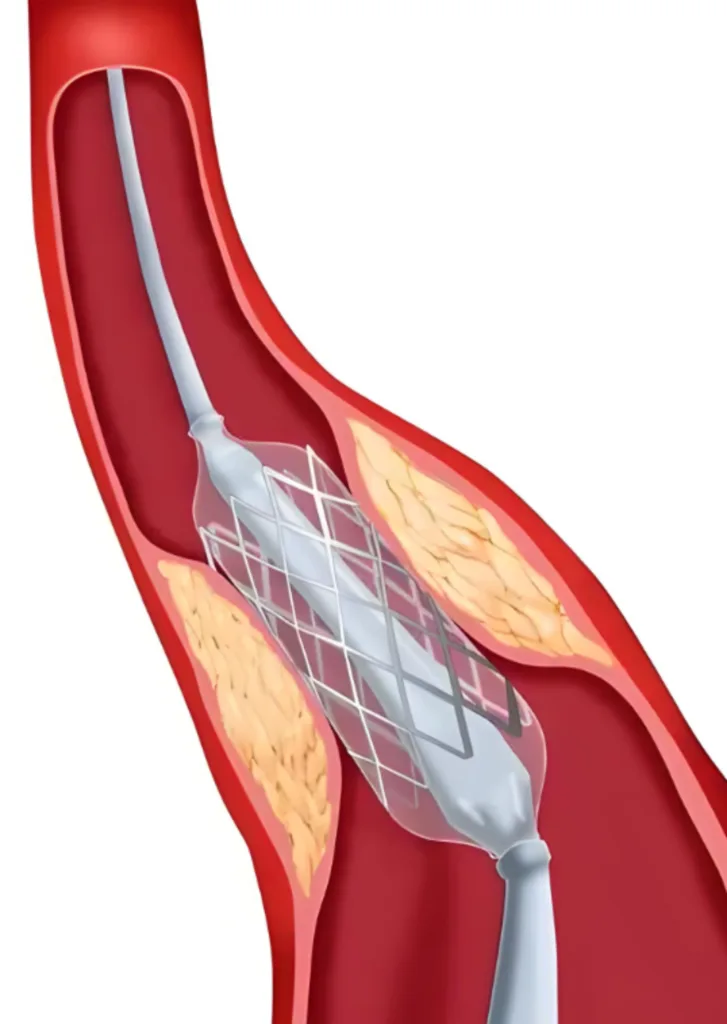

3. Cardiovascular Stents: Hair-Thin Wires Bearing Kilograms

3.1 Material Evolution: From “Bare Metal” to “Alloy Kings”

- First-gen stents used 316L but often triggered clotting; restenosis rates hit 30%.

- Current trend: Cobalt-chromium alloys (tensile ≥1340 MPa) allow beam thicknesses down to 80 μm—though stainless remains a cost-effective option for some cores.

A typical stent—2.5–4 mm in diameter—must endure millions of heartbeats. Its secret lies in:

- Ultra-fine grains: Precision rolling and heat treatment shrink grains to the micrometer scale, boosting strength by 30%.

- Drug coatings: Sirolimus layers on the surface suppress excessive cell proliferation, driving restenosis rates below 5%.

3.2 Manufacturing: Laser Precision & Nano-Finishing

- Femtosecond laser cutting sculpts complex mesh patterns from 1–2 mm tubes, with micron-level accuracy and wall thickness down to 70 μm.

- Electropolishing removes burrs, achieving surface roughness <0.1 μm to minimize thrombosis risks.

- Drug application provides sustained release over months.

3.3 Load-Bearing Marvel: Mesh Mechanics

Despite individual wires of only 0.08–0.1 mm diameter, the stent’s network design distributes radial loads evenly—each stent can withstand 5–10 kg of pressure, hundreds of times its own weight.

4. Space-Age “Rustproof” Tech: ISS Antimicrobial Innovations

4.1 The Space Toilet: Extreme Cleanliness

The ISS’s urine-reclamation plumbing uses 316L tubing to resist acidic urine (pH≈2). A nano-silver inner coating prevents bacterial growth in microgravity, avoiding clogs.

4.2 Atomic-Oxygen Corrosion: The Invisible Threat

At ~400 km altitude, high-energy atomic oxygen (10⁶ atoms/cm³) wreaks havoc beyond ordinary O₂. Countermeasures include:

- Gold plating on moving parts for inert protection.

- Silver- or copper-infused stainless for ion release that suppresses microbes in the closed environment.

5. Looking Ahead: Smart Materials for Next-Gen Medicine

- Biodegradable stents of magnesium alloys dissolve after vessel support, avoiding permanent implants.

- 4D-printed shape-memory alloys adapt to bone growth in orthopedic implants.

- Self-healing nanocoatings on surgical blades automatically regenerate an antimicrobial film after wear.

From the operating room to the space station, stainless steel’s “superpowers” keep expanding. With high-nitrogen, nickel-free steels and biodegradable magnesium alloys on the horizon, tomorrow’s medical devices will be safer and smarter—an enduring promise to life itself.